Your premier source for historically accurate Restoration Window Glass™. Our goal is to recreate period glass by using the same manufacturing process used in America from the 17th to the mid-20th century.

Connect With Us

The distinguished source for period Restoration Window Glass. Hollander is the premier manufacturer of Circa Wavy & Antique Glass. Circa Glass products combine historical accuracy with modern utility. We make our Circa antique & wavy glass, one sheet at a time, here in the USA. Check out one of our most popular products, Hollander Circa 1900™. This product boasts an elegant distortion that remains true to its historical aesthetic. Our antique & wavy glass production methods allow us to cater to a variety of applications by offering larger sheets and thicknesses than were originally possible for glass makers.

Learn Glass History

“Bravo to the whole team for faultless execution. I have been in the design business for over thirty years and I can’t make this claim as often as I would like!”

– Tom Gibb, Partner | Lindgren Gibb Studio

Hand-crafted antique & wavy glass products for architectural restoration and period recreation.

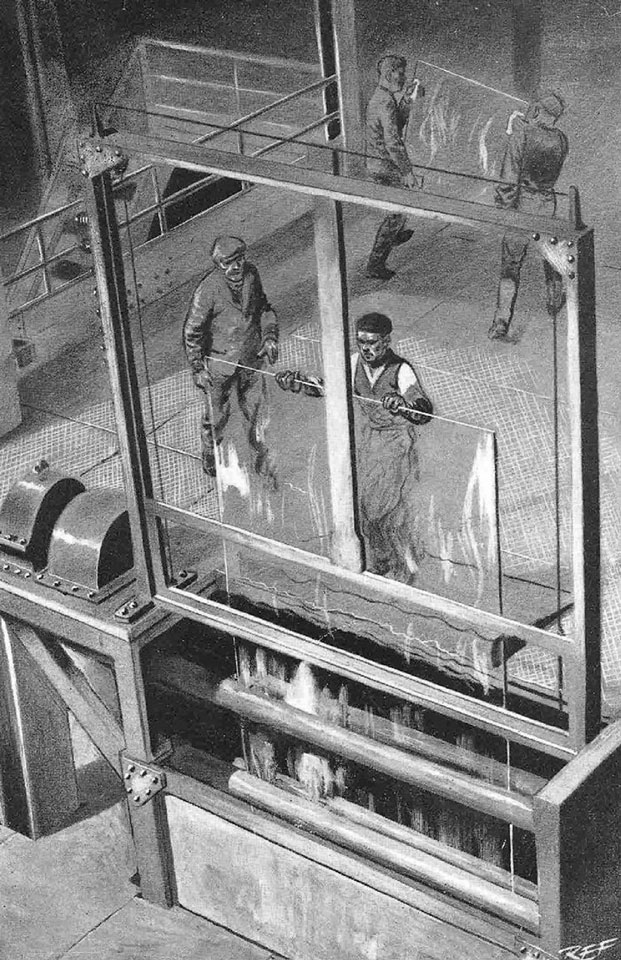

Cylinder & Crown wavy glass products that are hand-spun by Artisans using centuries-old methods.

Specialty Restoration Window Glass products with modern utility including Low Iron & Low-E products.

Dealer inquires are welcome or we will be happy to direct you to a retailer in your area.

Contact UsYour inquiry has been submitted. We'll get back to you as soon as possible.